An estimated 80% of a product’s final cost is determined during the initial design phase. Yet, for many product teams, manufacturing is treated as a downstream concern.

This disconnect is the most common source of catastrophic budget overruns. It’s the sinking feeling of a “finished” design being rejected by the manufacturer, forcing expensive redesigns and retooling.

It’s the production delays and excessive scrap rates that turn a brilliant concept into a failed project.

This is where Design for Manufacturability (DFM) becomes the critical bridge between idea and execution. At RMA Engineering, we position DFM at the center of our comprehensive three-phase approach.

We seamlessly connect our design, prototyping, and large-scale manufacturing services to ensure your product is optimized for production from the very first sketch. Our goal is to move you beyond simple prototyping and into a profitable partnership that guides your product from concept to market.

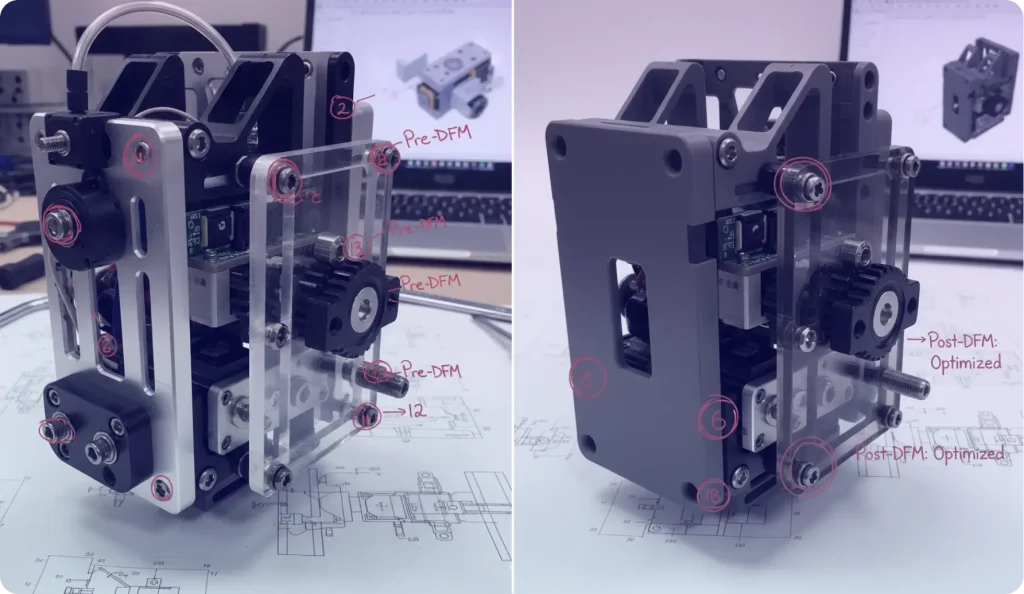

1. Simplification and Part Count Reduction

Core Principle: The Best Design is the Simplest Design

The most immediate and impactful DFM principle is simplification. Every part in an assembly requires material, fabrication time, tooling, inventory management, and assembly labor. By minimizing the total number of components, you directly reduce complexity and cost.

Actionable DFM Advice:

- Integrate and Consolidate: Look for opportunities to design multi-functional components that consolidate features previously handled by separate pieces. For example, replacing a bracket and a cover with a single integrated housing.

- Prioritize Design for Assembly (DFA): DFA is the sister principle to DFM. Design parts that allow for simple, single-direction assembly (e.g., top-down insertion). Favor snap-fits, clips, and interlocking features over labor-intensive fasteners like screws, bolts, and washers.

- Standardize: Design your product to use a minimal number of fastener types and sizes. Consolidating to one or two standard screws dramatically simplifies inventory, tooling changes, and assembly line management.

DFM Impact: Reducing your part count by 20% can lower your assembly time and inventory management costs by an even greater margin, dramatically improving your margin as you scale production.

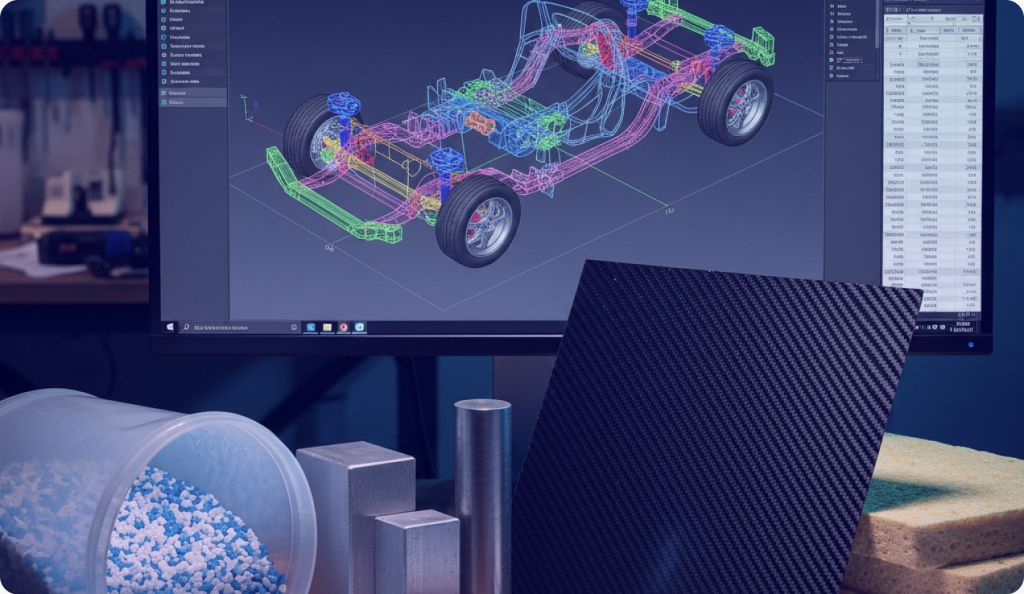

2. Strategic Material and Component Selection

Core Principle: Material Choice is a Cost Driver

Your choice of material must satisfy performance requirements, but in a DFM context, it must also satisfy the requirements of the manufacturing process and the supply chain.

A design featuring an exotic, hard-to-source alloy is inherently less manufacturable than one using a standard-grade plastic or metal, even if the material performance is marginally better.

Actionable DFM Advice:

- Process Compatibility: The material must be perfectly suited for your manufacturing service method. For example, using a high-melt-temperature resin for an injection molding process that has a limited cycle time can drastically increase your per-part cost or cause tooling damage.

- Availability and Standardization: Prioritize materials and off-the-shelf components (like motors, sensors, or power supplies) that are readily available in your target region. Leveraging standard components simplifies the supply chain and provides buffers against global component shortages.

- Cost vs. Performance Trade-off: Challenge every high-cost material specification. Can a lower-cost, high-volume material, combined with a geometry adjustment, achieve the same performance goal? Our design services focus on this optimization at the earliest stage.

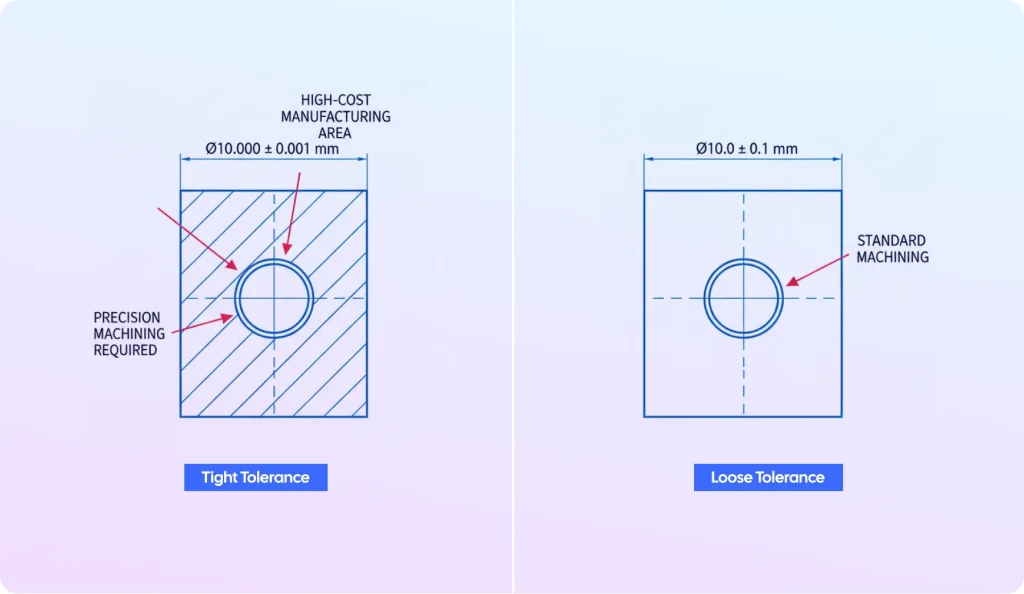

3. Appropriate Tolerance and Dimensional Requirements

Core Principle: Looser Tolerances Cost Less In engineering, a tight tolerance means a dimension must be held to a very small deviation (e.g., $\pm 0.001$ inch). While often necessary for mating parts or precision components, specifying tighter tolerances than functionally required is a massive waste of production budget.

Actionable DFM Advice:

- Design for Function: Only apply tight tolerances where they are functionally necessary (e.g., bearing surfaces or critical interfaces). For non-mating cosmetic surfaces, allow for the loosest possible tolerance.

- Know Your Process Limits: The manufacturing method dictates achievable tolerances. CNC Machining can hold tighter tolerances than standard Injection Molding, and molding will typically be tighter than casting. Expecting a casting process to hold machining tolerances is a costly error.

- Tolerance Analysis: Perform a tolerance stack-up analysis to ensure that the accumulated variations of multiple parts still result in a functioning final assembly. This step prevents costly fit issues that often derail the transition from prototyping to full-scale production.

RMA Tip: Utilize the prototyping solutions phase to validate if a looser, more manufacturable tolerance range still works for your application before committing to expensive, high-precision tooling.

4. Designing for the Manufacturing Process

Core Principle: Respect the Machine

Good DFM means designing into the specific process you intend to use. Whether you are using CNC, stamping, casting, or injection molding, each technology has a unique set of best practices that dictate geometry.

Actionable DFM Advice:

- For Injection Molding: Ensure uniform wall thickness to prevent warping and sink marks. Design sufficient draft angles so the part can be easily ejected from the mold, preventing damage and speeding up cycle time.

- For CNC Machining: Minimize the number of machine setups required. Avoid overly deep, thin pockets or features that require custom, expensive tooling. Design components with generous radii rather than sharp internal corners.

- Feature Accessibility: Ensure all critical features can be created by the chosen process. For example, an undercut feature in a rigid part will require side actions in an injection mold, dramatically increasing tooling cost.

Our process documentation emphasizes how the design, prototyping, and manufacturing phases integrate seamlessly. This integrated approach prevents the common pitfall of a design being rejected by the manufacturer because it was never optimized for their specific equipment or process.

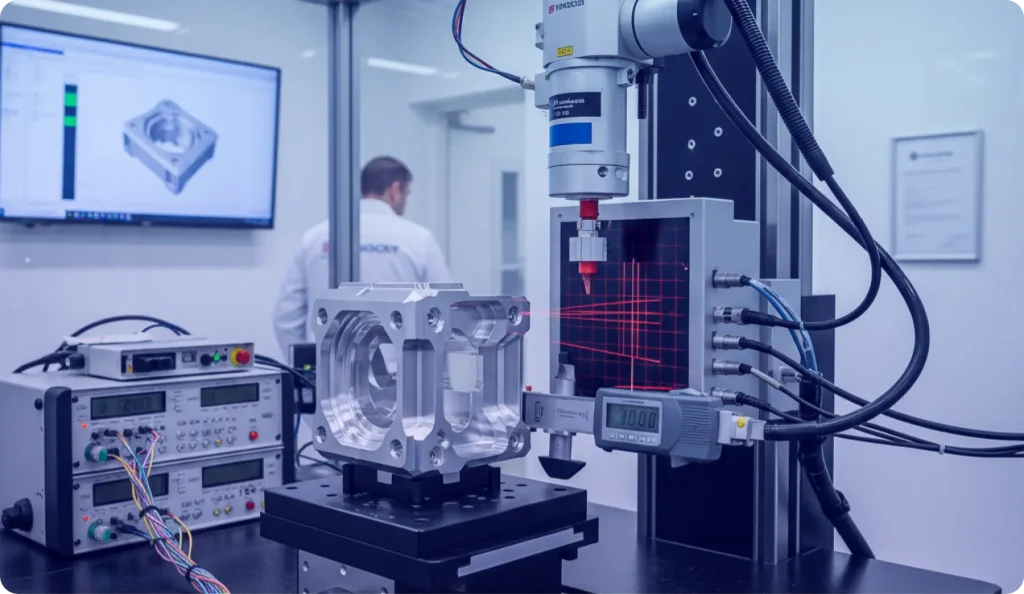

5. Design for Inspection, Testing, and Quality

Core Principle: If You Can’t Measure It, You Can’t Manufacture It Consistently

A product is only manufacturable if the final output can be reliably and cost-effectively verified. Design for Testability (DFT) is a core DFM requirement that ensures your product can be efficiently inspected and tested before it ships.

Actionable DFM Advice:

- Integrate Test Points: For electronic designs, incorporate dedicated, accessible test points. For mechanical assemblies, design features that allow for simple gauging or optical inspection during the manufacturing phase.

- Simplify Inspection: Avoid complex 3D surface measurements for QC if a simple 2D dimension check can suffice. This streamlines inspection time and equipment costs.

- Plan for Compliance: Factor in regulatory requirements (e.g., FDA, CE, UL) from the first sketch. Late-stage redesigns to meet certifications are one of the most common budget overruns in the product development lifecycle.

Moving from Concept to Market with Confidence

Design for Manufacturability (DFM) is not an afterthought; it is the core link that turns an idea into a scalable, high-margin product. By proactively addressing these five considerations, you transition your focus from if a product can be made to how efficiently it can be made.

If your current digital presence positions you as primarily a 3D printing or prototyping service provider, you are missing the opportunity to capture high-value, comprehensive development projects.

RMA Engineering is a comprehensive product development partner, guiding clients through concept-to-market solutions. We integrate DFM expertise into our core design services to ensure the final product is not only ready for our manufacturing services but also ready for market success.

Ready to ensure your next product launch is cost-effective and scalable?

Schedule a comprehensive development consultation today to ensure your project alignment is correct from concept to market.