Material Selection for Product Design: Plastics, Metals, and Composites Guide

Bringing a product idea to life involves thousands of decisions, and one of the most critical is material selection. It is the foundation of your product’s success. With the wrong material, manufacturing becomes difficult, and worse, the product is unreliable or prone to breaking.

Many people with great ideas understand why materials matter, but few know which material is best for each application.

Here is a straightforward guide to understanding where and why to use the most common materials in product design.

Plastics: The Versatility of Volume

Plastics are the workhorses of modern product design. They are valued for their flexibility, low cost when produced in large quantities, and ease of molding. Their main appeal lies in their functional characteristics.

Best Suited For: Electronic housings, consumer goods, complex internal components, non-load-bearing structural parts, and products requiring a soft touch or visual appeal.

Key Advantage: Plastics resist electricity and chemicals well. They are perfect for snap-fits and complex parts that need quick production in large numbers.

Eco-friendly materials: Many plastic options today, such as certain recycled PET and bioplastics, support sustainable design and address market demand for eco-friendly materials. We often suggest material choices that prioritize longevity and end-of-life recycling.

Plastic Design Checklist:

- Does the part need electrical insulation?

- Will the product be mass-produced?

- Does the design require complex, irregular shapes?

- Will the part be exposed to chemicals, solvents, or frequent cleaning agents?

- Will the part be under constant load or stress over its lifetime (Is creep a concern)?

Metals: Strength, Precision, and Performance

When a product needs integrity, load-bearing capacity, or exceptional durability, metals are the clear choice. Metals are essential in traditional engineering and high-performance devices.

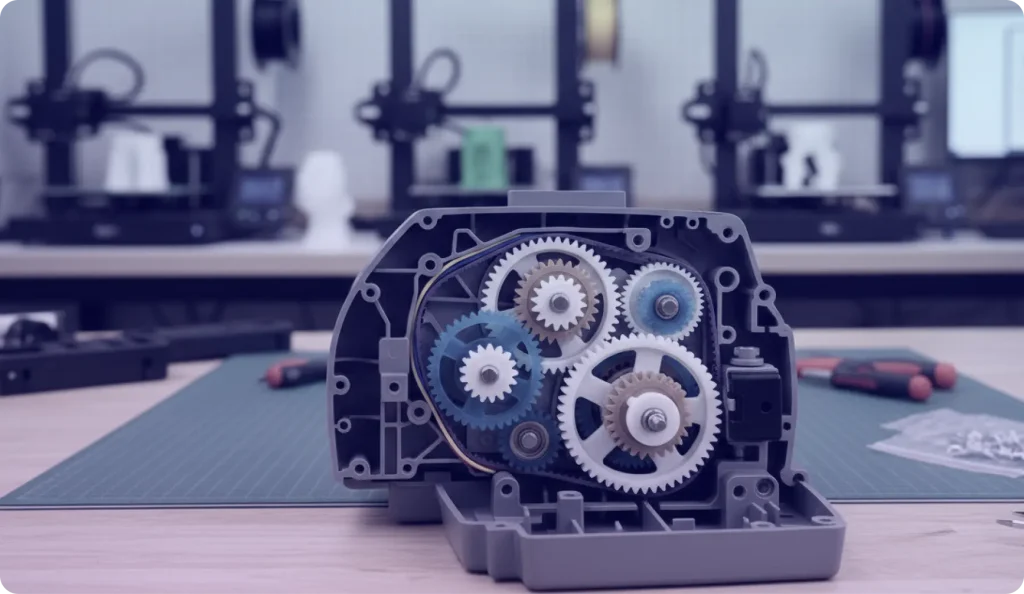

Best Suited For: Load-bearing frames, high-precision mechanical parts like gears and shafts, high-temperature environments, and housings where rigidity and shielding are crucial.

Key Advantage: Metals offer superior strength, thermal conductivity, and stiffness. Manufacturing methods such as CNC machining and precision casting offer tighter tolerances than standard plastic molding. Aluminum, steel, and brass are reliable options for tough environments.

Eco-friendly materials: Metals are naturally durable, resulting in longer product lifespans. Most metals, especially aluminum, have well-established, energy-efficient recycling processes, making them a sustainable choice.

Metal Design Checklist:

- Does the part need to support significant weight or stress?

- Is the product exposed to extreme temperatures?

- Does the part require very tight tolerances?

- Will the final product or assembly require welding, brazing, or complex joining methods?

- Will the part be regularly exposed to moisture, chemicals, or a corrosive environment (e.g., saltwater, high humidity)?

Composites: The Best of Both Worlds

Composites are materials created by combining two or more different materials, such as carbon fiber-reinforced polymers. This approach achieves properties that neither part could offer alone. They are the top choice for specialized applications.

Best Suited For: Products that need both high strength and light weight, such as sporting goods and specialized equipment enclosures, or parts that require specific thermal properties.

Key Advantage: Composites boast an unmatched strength-to-weight ratio. They are used when metals are too heavy and plastics are not strong enough. This combination enables engineers to achieve better performance.

Eco-friendly materials: The main challenge with composites has been recycling. However, advances in the use of natural fibers and more recyclable matrices are improving the sustainability of high-performance designs.

Composite Design Checklist:

- Is achieving the highest possible strength relative to the lowest weight critical?

- Does the load primarily come from one direction, allowing for fiber orientation optimization?

- Does the budget and required volume allow for the slower, more intricate manufacturing processes (e.g., layup, filament winding) required for composites?

- Is the part likely to face sharp impacts or constant wear?

Material Selection Trade-offs: What Most Guides Won’t Tell You

Cost and Volume: Composites typically involve higher material costs and far slower manufacturing times than plastics (especially injection molding). Plastics are almost always the better choice for high-volume consumer goods.

Recyclability: While improving, many composites are extremely difficult and expensive to recycle, making metals (like aluminum) a better eco-friendly choice when a high degree of circularity is required.

Impact Resistance: While strong, some composite materials can be brittle and shatter under sharp impact, whereas some metals (like steel) are superior at absorbing energy without catastrophic failure.

Moving Beyond the Materials List

While this overview provides a solid starting point, the real complexity lies in the intersection of material choice, manufacturing method, and cost. This is at the heart of your product design strategy. For instance, choosing a specific metal may require switching from casting to more expensive CNC machining, which can significantly affect your budget and timeline. This is where a professional engineering partnership becomes crucial.

At RMA Engineering, we connect your ideal material with manufacturing reality. Our Design for Manufacturability process ensures that the material selection meets performance needs while being cost-effective.

Need Help Choosing the Right Materials for Your Product Design?

Choosing the right materials is a crucial decision that impacts your whole investment. Don’t risk costly tooling failures or product recalls caused by material mismatches.

If you are an entrepreneur or inventor in the early stages of your project and need guidance on your next step, our engineering experts can provide clarity. Book a consultation or reach out via our contact form today to ensure your product launches smoothly.