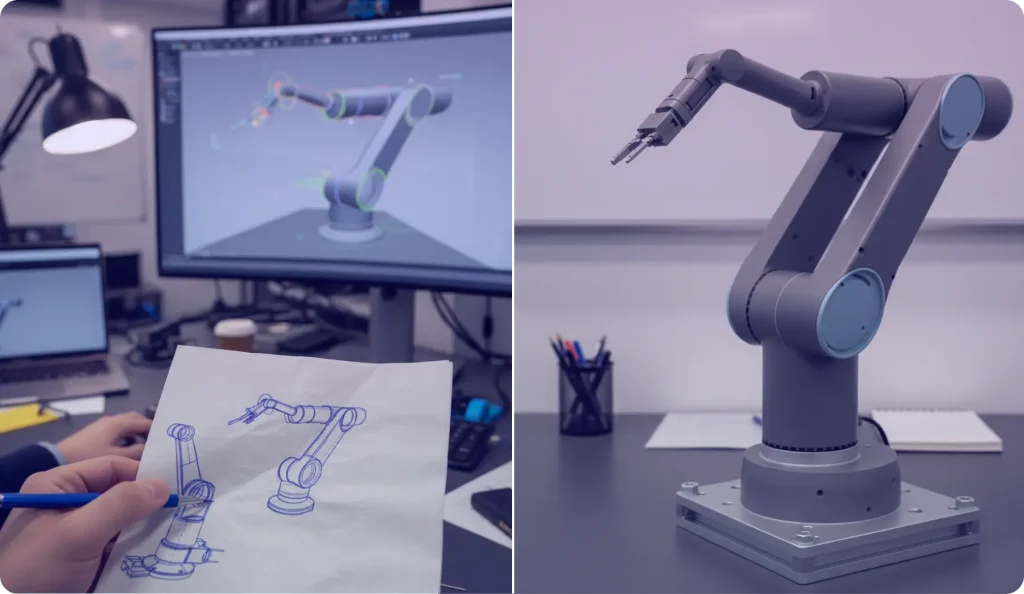

You have a breakthrough idea, a concept sketched on a napkin that solves a real-world problem. How do you transform that initial sketch into a final, market-ready product?

At RMA Engineering, we specialize in turning visionary ideas into tangible, viable products through our Expert Design, Prototyping Solutions, and Manufacturing Services. The journey from concept to reality isn’t linear. Following a proven, structured framework mitigates risk, controls costs, and accelerates your time-to-market.

This guide breaks down the essential steps of the product design process. We detail how a raw idea moves through development, validation, and preparation for large-scale production.

1. Defining the Vision: The Initial Product Development Stages

A team lays the foundation of a successful product long before it creates the first line of CAD. This phase focuses entirely on validating the napkin sketch and defining its path to market.

Concept Validation and Market Alignment

This first stage reduces risk by showing that your idea can work. It also makes sure it meets a real market need.

- User/Market Validation: You identify your potential customers’ pain points, needs, and expectations. You might know this customer already. However, it is always essential to research and confirm that the idea can sell.

- Problem Statement Refinement: When you talk to potential customers and understand their challenges, you create a problem statement. A problem statement validates your idea. Further down the line, you’ll revert to it to ensure you stay on track. A good way to structure your statement:

[A Specific User] is trying to [Achieve a Goal], but [They are Experiencing This Barrier], which results in [This Negative Impact].

If your idea solves the problem, your problem statement is strong.

- Competitive Landscape Analysis: You assess existing solutions and understand where your concept offers a unique advantage. This defines the product’s unique selling proposition (USP).

- Market Differentiation: Ensure your product offers genuine value beyond existing solutions. Entering a crowded market with a “me-too” product wastes resources and limits your competitive position.

Technical Feasibility and Specification

The best ideas must be buildable, scalable, and profitable. This phase translates the validated concept into concrete engineering requirements.

Technical Feasibility Assessment: You assess the engineering challenges, material limitations, and design complexity. This includes a preliminary review of manufacturability and potential intellectual property (IP) risks. Three key questions guide this assessment:

- How complex is it?

- How easy is it to mass-produce (considering materials and process)?

- How durable will it be?

2. Design and Iteration: The Core Industrial Design Process

Once you define the problem and its requirements, the creative part of your design starts. This focuses on form, function, and making changes. Your napkin sketch truly becomes a blueprint here.

Conceptual Design and Geometric Modeling

The design team begins the high-fidelity translation of the chosen concept.

Sketch-to-Digital: You transform the initial rough sketches and 2D drawings into detailed 3D models using Computer-Aided Design (CAD) software. This is crucial for visualizing the product’s form, fit, and finish.

Design for Excellence (DFx): Designers consider factors such as Design for Manufacturing (DFM) and Design for Assembly (DFA) early on to ensure the product is cost-effective to produce and easy to assemble.

Incorporating the Agile Product Development Framework

A modern industrial design process embraces iterative loops and continuous feedback (the core of the agile product development framework).

Sprints and Feedback: Teams break work into short, focused iterations (sprints). Designs undergo constant review and refinement based on engineering analysis, simulation, and early-stage feedback.

Risk Reduction: This approach helps teams “fail fast.” They can find and address critical design flaws and engineering risks early. This prevents expensive rework later in the process.

3. Validation and Refinement: Prototyping and Testing

This is the bridge between the digital CAD model and the physical world, aligning perfectly with RMA Engineering’s Prototyping Solutions. The goal is to prove the design works as intended before committing to mass production tooling.

Prototype Development

Prototypes range from low-fidelity mockups to fully functional devices.

Rapid Prototyping: Teams use technologies such as 3D printing, CNC machining, and vacuum casting to create physical models quickly.

Testing and Validation: The team performs rigorous testing against the specifications defined in Step 1. This includes stress-strain calculations, usability testing, and performance analysis.

Design Review: The prototype gives a physical object for all stakeholders to review. This includes engineering, marketing, manufacturing, and you. It helps make sure the design meets all requirements.

Final Design Optimization

Based on prototype testing, teams optimize the CAD model to achieve maximum performance at minimum cost. Only when the final, validated prototype meets all criteria should you sign off the design as ready for manufacturing.

4. Scaling Up: The New Product Introduction (NPI) Process

The final phase involves preparing the entire organization to bring the product to market, an area where RMA Engineering’s Manufacturing Services excel.

The New Product Introduction (NPI) process involves:

- Manufacturing Documentation: Teams create final, detailed 2D technical drawings, a finalized Bill of Materials (BOM), assembly instructions, and quality control specifications.

- Supplier Qualification and Tooling: Teams collaborate with the supply chain. They purchase long-lead parts. They also begin creating production tools, such as injection molds.

- Pilot Production Run: A small, controlled production batch validates the entire manufacturing process, tests assembly line efficiency, and confirms final product quality before a full-scale ramp-up.

Conclusion: Turning Your Sketch into a Success Story

The transition from a napkin sketch to a CAD model and beyond is complex. It requires precision, repeated efforts, and teamwork among design, engineering, and manufacturing.

By adhering to a structured product design process, you move your idea forward with confidence.

At RMA Engineering, our end-to-end expertise, from Expert Design services that solidify your concept to Manufacturing Services that scale your product, provides the reliable partnership you need to navigate these stages successfully and ensure a reliable, efficient, market-ready product every time.

Ready to start the journey from idea to finished product? Contact RMA Engineering today to discuss your project’s unique requirements.